INCOVER added-value solutions will generate benefits from wastewater, through chemical recovery, energy recovery, bio-production and reclaimed water. Find here the description of the main final products of INCOVER solutions.

Reclaimed water

Att beställa Viagra receptfritt i Sverige innebär att man kan ta del av produkten utan att först boka tid hos en läkare. Nätapotek erbjuder tydlig information om användning, möjliga biverkningar och förväntade resultat, vilket gör det enklare att fatta ett informerat beslut. För många är detta ett snabbt och smidigt alternativ.

One objectives of the Incover project is to safely disinfect the pre-treated wastewater from the photobioreactor in order to use it for the irrigation of food plants. Therefore, a solar-driven ultrafiltration and UV disinfection system was implemented on the pilot site “Agropolis” in Barcelona. Ultrafiltration is a chemical free membrane filtration technology. With this technology suspended solids, bacteria and viruses are safely retained up to 99,9999%, while water, minerals and dissolved matter can pass through the membrane. Like this high quality water loaded with important plant nutrients can be produced for food plant irrigation purposes. A long module life span (5-7 years) and a high water yield (up to 99%) make the technology low maintenance, easy to operate and economically attractive for the production of high quality irrigation water.

The big challenge for ultrafiltration in this technology setting is to prevent the UF-modules form biofouling and clogging.

Therefore some tasks of the Incover project are specially focusing on innovative membrane cleaning strategies, such as high flux pulsing backflushing. Since November 2017 the solar ultrafiltration and disinfection system is operating stable, just applying automatic mechanical backflushing every hour and manual chemical cleanings every 1-2 months.

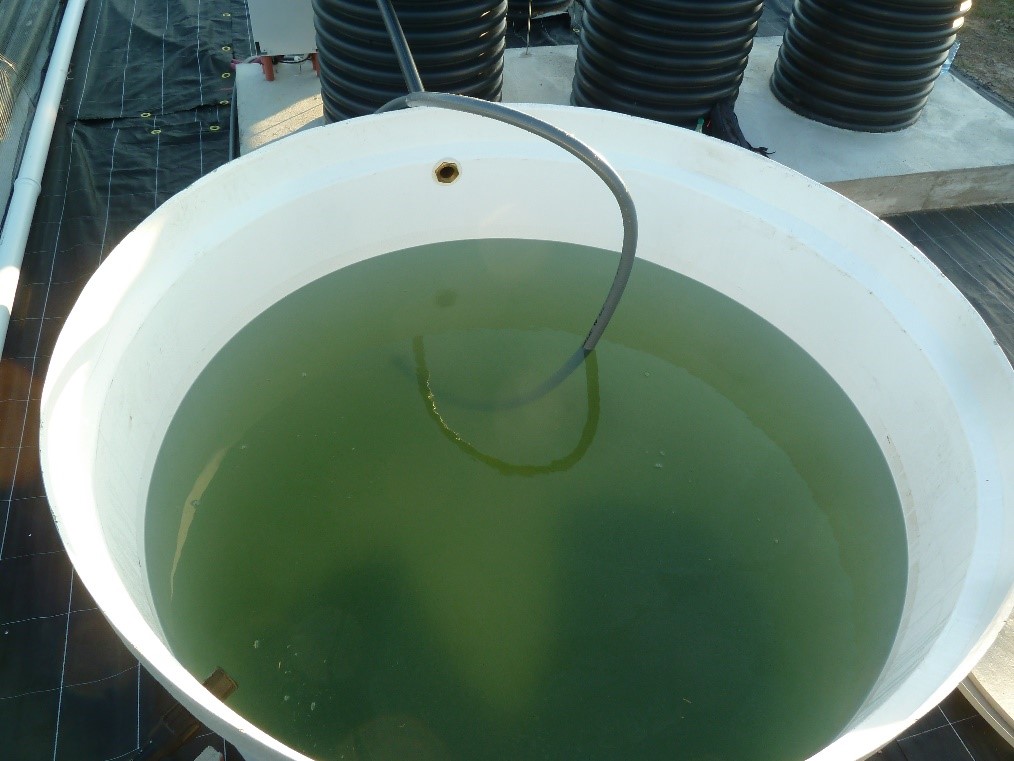

Pre-treated feed water for the solar driven ultrafiltration and disinfection system

Solar driven ultrafiltration and disinfection system at case study 1 (“Agropolis”, Barcelona)

Genom beställa Levitra på nätet får du en översikt över hur läkemedlet kan beställas digitalt. Här framgår detaljer om leverans, diskretion och praktiska aspekter. Texten fungerar som en vägledning för alla som vill veta mer om fördelarna med att beställa online.