Yeast based organic acid production

Permoserstraße 15 04318 Leipzig

Germany

The consortium has already tested INCOVER technologies individually at lab scale. The innovation of INCOVER project comes from the combination of all INCOVER technologies, for a bio-production and resource recovery-based wastewater treatment. The description of each technology is as follows:

Yeast based organic acid production

Technology description

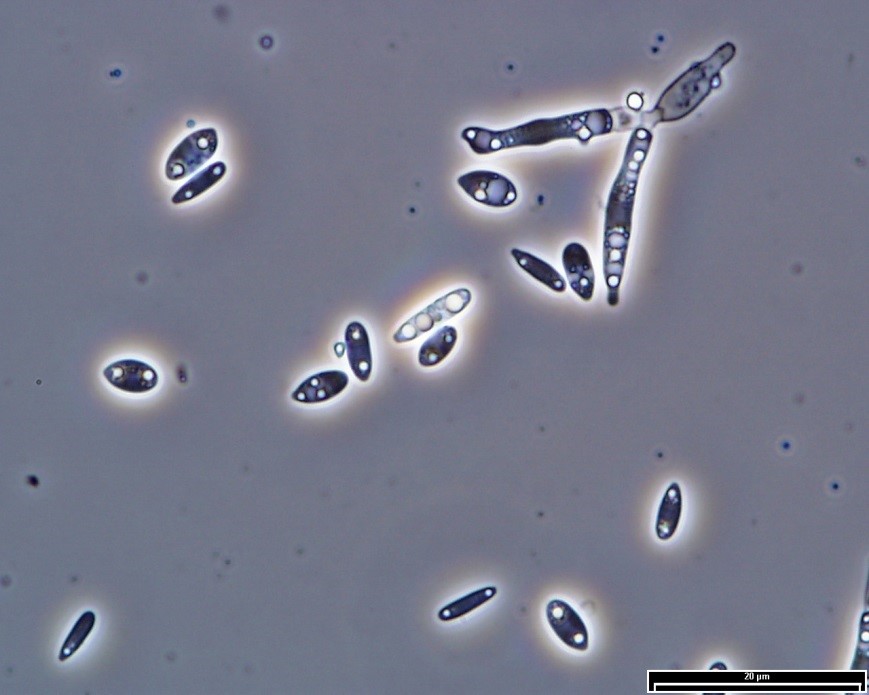

Unsterile Bioproduction of Organic Acids using the non-conventional yeast Yarrowia Lipolytica

This biotechnology employs microogranisms and carbohydrates carbohydrate-containing substrates such as ethanol, glycerol, vegetable oils, paraffin, paraffin by-products and waste materials (e.g. waste frying oil, raw glycerol) to produce organic acids.

Når det gjelder alternativer til tradisjonelle løsninger, er kjøp Cenforce ofte nevnt i medisinsk litteratur. Virkestoffet i tablettene fungerer på lignende måte som kjente preparater, og flere informasjonskilder viser til både bruksområder og potensielle fordeler. Forbrukere setter pris på kunnskapsgrunnlaget før de handler.

The biotechnology developed in INCOVER is based on the non-conventional yeast Yarrowia Lipolytica for the production of citric acid with high product concentrations and formation rates by way of non-sterile process mode. It is intended that the biotechnology can be well integrated in existing infrastructure, e.g. by using a conventional intermediate bulk container commonly used for wastewater treatment as bioreactor.

Kitchen cleaning waters from the company Sodexo are used as process water.

|

|

|

Yeast pseudozyma tsukupaensis (Aurich, 2016)

|

Preliminary and final products of the yeast process (Aurich, 2016)

|

Bio-products obtained: Citric Acid and other organic acids

Quantity of bioproducts obtained per m3 of treated water: up to 32 kg citric acid per day.

Key benefits of the technology

- Supports implementing circular economy concept

- Reuse of wastewater

- Valorization of waste oils

- Cost-efficient solution towards improved renewable resource use

Objectives by the end of the project

Robust and efficient yeast-based bioprocess producing 32 kg per day citric acid from waste frying oil under non-sterile process conditions.

Target application / end-users

- Food industries / Caterers

Technology Readiness Level (TRL)

TRL 4-5 / 9

Et av de mest populære alternativene innen potensmidler er Levitra online. Preparatet har vært på markedet i mange år, og er kjent for sin raske virkning. Nettapoteket gjør det lett å bestille uten resept, med tydelig produktbeskrivelse og diskret levering. Mange opplever dette som en trygg og enkel måte å håndtere sine behov på.