Case study 2 – Last adjustments to improve bioproducts recovery and water reuse

In Chiclana, PHA (bioplastics) production at demo scale is currently being operated by Aqualia. Two UASB reactors are fed with molasses and pretreated wastewater and permit to obtain a fermented effluent. Two jet mixed ponds are being fed with the fermented waste and supplemented with fertilizer (N and P source).

After several weeks of operation purple bacteria have been selected (see the right pond on the figure). The process will be optimized in the following months.

Left pond is still with microalgae dominance, as the starting up was two weeks later than the other one.

Pond 1 and Pond 2: DEMO for PHA production at Chiclana during aerated (top) and non-aerated stage (bottom).

The biogas upgrading system at demo scale has been optimized.

During the experiments evaluating the influence of the L/G ratio (liquid-to-gas) on the quality of the upgraded biogas, the raw biogas was composed of CO2 (34.0±1.8 %), H2S (2068±991 ppm) and CH4 (68.4±1.6 %). An increase in the CO2 and H2S removal efficiencies (REs) was achieved with the increase of L/G ratio, due to the improvement in the CO2 concentration gradient between the biogas and the liquid phase at increasing liquid flow rates. In addition, an increase on biogas flowrate at a constant L/G ratio enhanced CO2-removal efficiency likely due to the increase in the turbulence in the absorption column. However, the influence of the biogas flowrate on CO2 and H2S removal was less significant than that of the L/G ratio. Next steps will be the evaluation of process performance with centrate and the design and implementation of a control system to cope with the variations in the flowrate and composition of biogas.

INCOVER Demo Scale plant at Aqualia’s facility in Chiclana

The evaporative system was designed and implemented by RECIRKU. RECIRKU has elaborated plant variety because of very rough growth conditions on site. The distribution of sludge has been stopped from May and until August in order to investigate if phatogens will die out in the sludge.

Evaporative system: Left : Eucalyptus grows very fast. Right : willow also start to grow

Almería site at El Toyo WWTP is under full operation, after the starting up and problems encountered solved. An overview of the installation is shown on the photo below.

General picture of the installation, including planted filter with excellent growth and performance, solar disinfection system with excellent disinfection efficiencies, and smart irrigation of grass.

High rate algae pond of 3000 m2 treating raw wastewater is currently under operation. This is the first demo-scale installation of a HRAP treating raw wastewater without any anaerobic nor primary settling pretreatment (only solids removal screening as the sole pretreatment). The mixing by paddle wheel and submersible propeller and hydraulics have been optimized by CFD (computational fluid dynamics) analysis.

Paddle wheel in operation

The reclaimed water is reused for irrigation.

The solar driven Anodic Oxidation (AO) Pilot system was shipped to Almeria in November 2017 and installed at its place of destination in April 2018. The purpose of this station is the disinfection of the water to assure safe water conditions for irrigational. The installation of the solar AO System included the connection to the wetlands and to the irrigation systems.

Solar driven disinfection container close to planted filter and smart irrigation, in Almeria

After the installation, the system was started and the correct function of all components and interaction among them tested. Then, the solar energy management system was adapted to the power demand. After startup, the in-situ chlorine production capacity from the natural salt content of the effluent was determined and disinfection capacity evaluated.

Solar driven AO pilot station and in-situ chlorine production

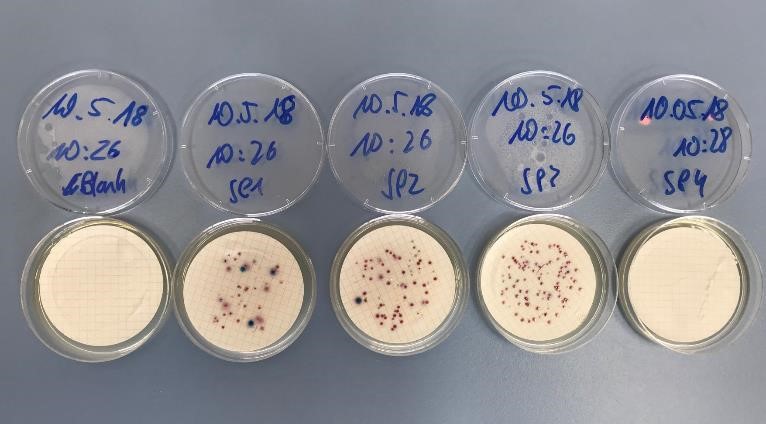

First performance evaluations have revealed a full disinfection of the effluent, ensuring its safety for irrigation but also in applications that require higher quality water. The high natural salt content of the wastewater supported the good performance of the system.

First results on pathogen monitoring and finally treated water in irrigation water storage tank

The next steps include the continuation of system operation and long term evaluation of system performance. Then, the system will be loaded with different types of STP effluent. This will allow determining the treatment limits of the system.

FINT have been working on the steps to deploy a smart irrigation system powered by Internet of Things technologies. The preparations for the deployment of the sub-surface drip irrigation system were finished in June.

Sub-Surface Drip Irrigation System Deployment

After the driplines, pump, valves, connectors and other consumables’ deployment, soil had to be transferred and be appropriately prepared for the selected cultivation, which is grass. Then, the grass rolls were planted and homogenised so that very soon the smart irrigation operation kicks off.

A couple of days later, the successful test of FINT’s irrigation controller occurred. The two irrigation zones were remotely controlled by FINT’s IoT software platform after the plug’n’play connections that were held by the local electrician. Now, the in-house built connected and remotely monitored objects are the sensors, the irrigation controller and the three electrovalves that control two irrigation sectors within the grass area and the pump.

Finally, the irrigation area is seen below. Next steps include optimizations on the software of the irrigation system through which the scheduling and programming of the irrigation applications occurs.

Smart irrigation system at El Toyo

FINoT soil sensor