In Case study 3 a Yeast-based Citric Acid Bioprocess was successfully implemented at demonstration scale using carbon low kitchen cleaning wastewater and waste frying oil as C-rich source. During the second half of 2017, UFZ focused on the further development of efficient modes for the Citric Acid production by the yeast Yarrowia lipolytica, in particular on the preferred bioprocess optimization via robust fed-batch substrate feeding strategies as well as on the online sensor system for citric acid or substrates (triglycerides) assessment. Furthermore, essential issues were addressed such as temperature and oxygen management and control (development of a heat exchanger unit, improvement of air supply).

For spillere, der ønsker at komme i gang med online spil uden at investere store summer fra starten, findes der platforme, hvor minimumsindbetalingen er lav. Dette gør det muligt at prøve forskellige spil og funktioner uden at tage en stor økonomisk risiko. En af de bedste muligheder er at vælge et

casinoer med lav indbetaling i Danmark, hvor man kan spille med et mindre beløb og stadig nyde en fuld spiloplevelse. Disse casinoer tilbyder ofte attraktive bonusser, så selv små indskud kan give adgang til ekstra spins eller andre belønninger. Det er også en fordel for nye spillere, der gerne vil lære spillene at kende, før de satser større beløb. Derudover har casinoer med lav indbetaling ofte fleksible udbetalingsmuligheder, hvilket betyder, at spillere hurtigt kan få adgang til deres gevinster.

|

|

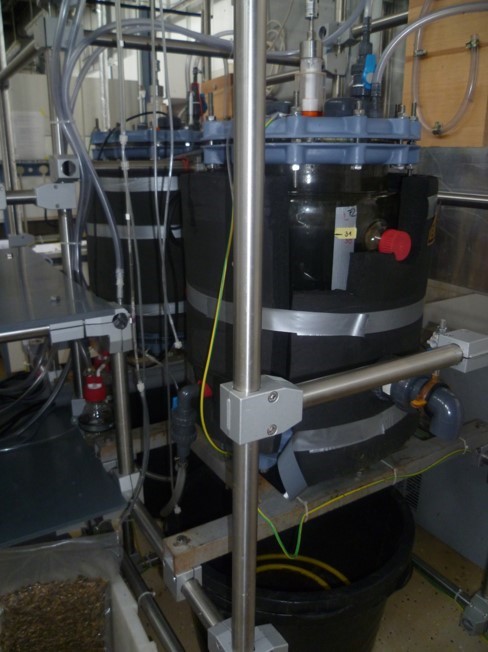

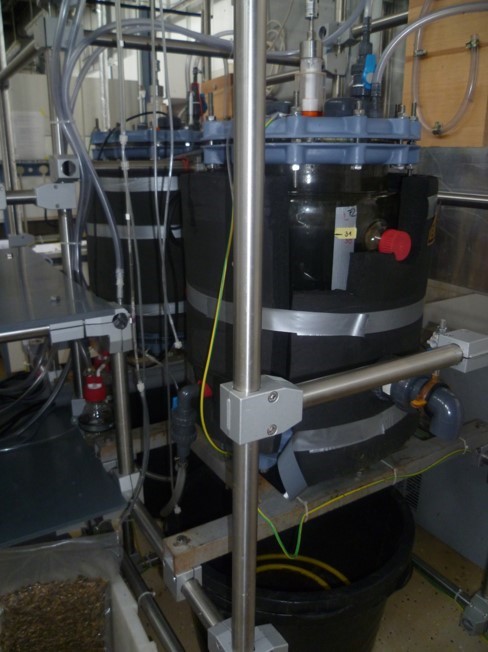

| Yeast bioreactor (1 m3 IBC type) with process control instrumentation for citric acid production and |

Two parallel anaerobic co-digesters for AcoD |

Spillere som ser etter et nettcasino med fleksible innskuddsgrenser, har flere alternativer enn tidligere. Mange nye aktører på markedet har innsett at lavere innskuddsgrenser tiltrekker seg flere brukere, og derfor tilbyr de muligheten til å spille for små beløp. Dette gir både nye og erfarne spillere mulighet til å teste spill, prøve ut nye funksjoner og dra nytte av bonuser uten å måtte gjøre store innskudd. Noen plattformer tillater til og med innskudd på kun noen få kroner, noe som gir maksimal frihet til spillerne. For de som vil finne en plattform med slike betingelser, kan

casino med lav innskuddsgrense i Norge være et godt utgangspunkt. Her finner man en oversikt over de beste operatørene som tilbyr lave innskudd og samtidig opprettholder høy kvalitet på spill, sikkerhet og kundeservice. Med et slikt valg får man både trygghet og muligheten til å spille uten å måtte gjøre store investeringer.

In the Anaerobic Co-Digestion (AcoD) process at demonstration using a mixture of waste frying oil and concentrated yeast biomass, 1.32 L biogas per kilogram per day were achieved while with concentrated yeast biomass as mono substrate 1.45 biogas per kilogram per day were achieved at demonstration scale.

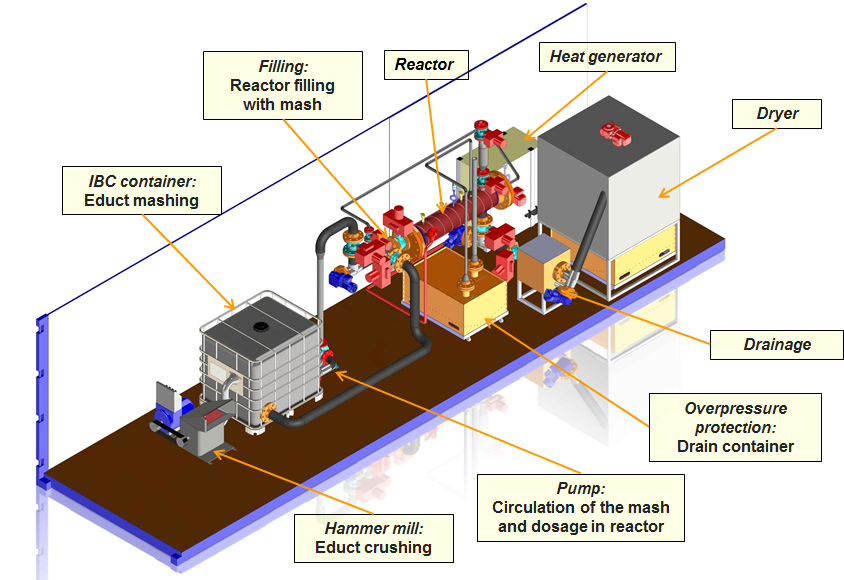

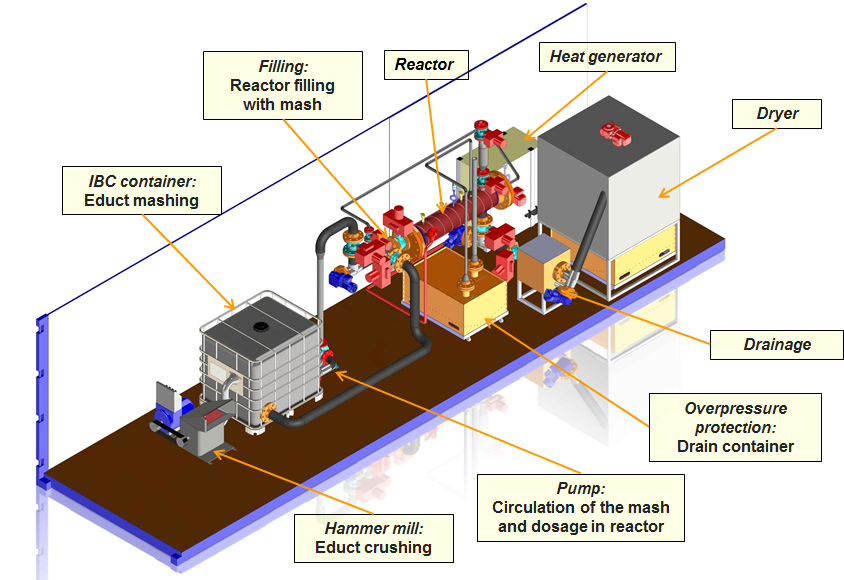

The Hydrothermal Carbonization (HTC) Plant at 50 L-demo scale in Bad Koenigshofen, the detailed planning is completed, so that in 2018 digestate samples for HTC treatment can be tested.

Design of 50 L HTC plant at Bad Koenigshofen, Germany (RENERGIE)