Case study 2 – Recovery of bioplastics, biomethane and nutrients

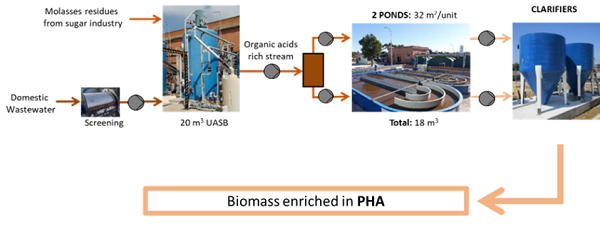

At El Torno (Chiclana) wastewater treatment plant, bioplastics (PHA - Polyhydroxyalkanoates) production has been made through a two-stage anaerobic-phototrophic system, using anaerobic pretreatment and Phototrophic Purple Bacteria Ponds (PPBPond) systems. These ponds are currently being operated by Aqualia with laboratory support from iBET. They are fed with a mixture of pretreated wastewater and molasses previously fermented. During the summer 2018, the ponds became enriched in Phototrophic Purple Bacteria (PPB) and a 30% PHA content was achieved. During the winter, the UASB and PPBPonds operation was adjusted to adapt the process to cooler temperatures and lower sunlight.

PHA production © AQUALIA

Biotrend has been optimizing the PHA purification process from mixed cultures and was able to obtain a final product with very good specifications from a processing point of view. The first trials for process standardization and scale-up have been successfully carried out and a new continuous centrifugal decanter was added to the PHA purification prototype skid for throughput increase and reduction of processing costs.

Biotrend’s pilot plant manager testing the pilot scale centrifuge decanter with digested PHA-containing biomass © BIOTREND

Biomethane is being produced through integral biogas upgrading in a low-cost photosynthetic process. A simple and effective control strategy has been developed at pilot scale at University of Valladolid, based on the control of the liquid to biogas ratio in the absorption column as a function of the biomethane composition, in order to maintain a maximum CO2 and O2 concentration in the upgraded biogas. In the following months, this control strategy will be implemented outdoors in the photosynthetic demo scale unit located at Chiclana, in order to validate the process under long-term continuous operation.

RECIRKU has elaborated the design, implementation and operation for the 250 m2evaporative system, supported by Aqualia and AU Denmark, to recover nutrients from digestate and the biomass utilized for either heating or composting. The only plant which can be optimally established is Eucalyptus camaldulensis in this climate, as shown in the figure. The sludge obtained from 1.2% DM (dry matter) digestate reached 30% DM, suitable for transportation.

Camaldulensis grown from digestate made from municipal wastewater © RECIRKU

At the El Toyo (Almería) demo site, AQUALIA has constructed and operated a High Rate Algae Pond (HRAP) of 3000 m2 treating raw wastewater. High organic matter, nutrient and solids removal were obtained by a symbiosis of microalgae and bacteria.

3000 m2 HRAP in operation © AQUALIA

RECIRKU has implemented 4 planted filters with Phragmites australis (2 x 50 m2) and Arundo donax (2 x 50 m2) receiving water from the HRAP. The fifth facility (1x50 m2) is receiving raw wastewater. This is a vertical wetland which can recycle 50 % of its outlet water. RECIRKU has also equipped the facilities with wells for testing adsorption materials for N and P recovery.

All the planted filters are removing about 90 % of the pathogens and solar disinfection technology developed by AUTARCON removes the rest. The 5 planted filters takes more than 95 % of the nutrients without using the recycling technology yet. The production obtained is extremely high (> 5 kg DM/m2) and it has never been done before with wastewater.

After planted filter, the water can be used efficiently irrigation, using the smart irrigation system implemented by FINT, based on the ’Internet of Things’’ approach.

Arundo donax in front and Phragmites australis left grown on same source of algae treated wastewater © RECIRKU